Description

EN 12697/22

For asphalt samples.

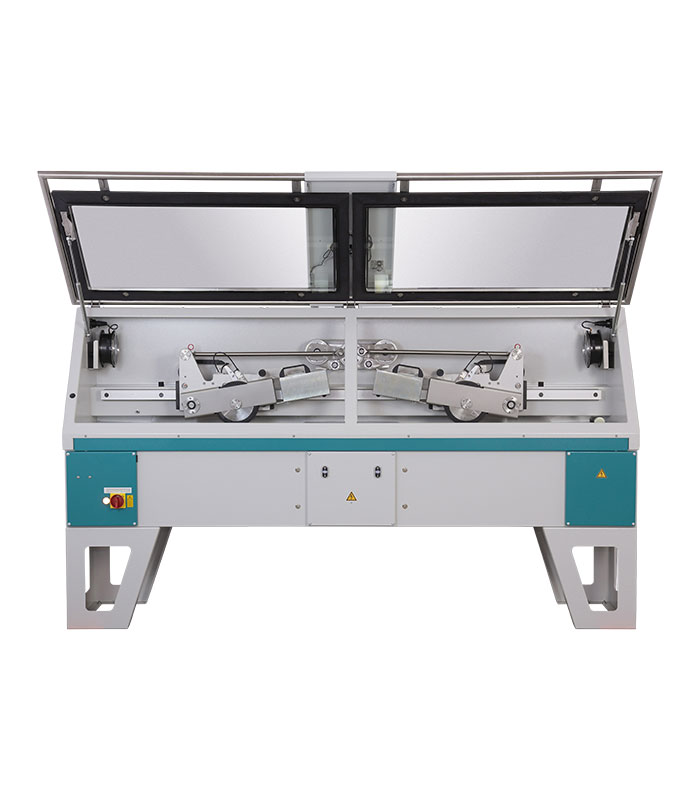

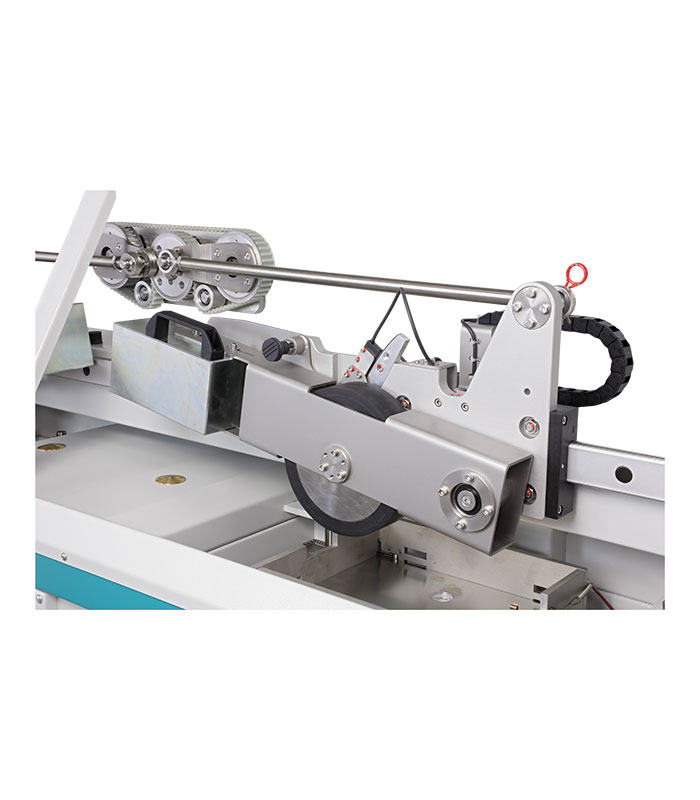

The apparatus consists of a steel plate casing and a hinged cover with viewing glasses. Two measuring places with rolling wheel units guided in precision bearing elements and driven by a frequency controlled motor with omega-synchronus belt drive are installed. Load is applied via a lever system. The inside can be heated with a hot-air blowing system. To enable the installation of samples into the testing place, both rolling wheel units can be stopped in a parking position outside the testing area. The two sample base plates of the machine are prepared for the installation of either mould spanner sets (20-4020..23) or plaster moulds (20-4015..16). Included are two easily interchangeable rolling wheels with rubber coating. Stainless steel rolling wheels 20-4000E100 are available on request. Two motorized lifting units controlled by the integrated software are used to sink down the wheels at the beginning of a test and to lift them up afterward. The whole process including heating, registration of test temperatures, number of overrollings and tracking depths is software controlled with the possibility of print-out and selectable testing programmes. The user himself can create and memorize his own test sequences and programmes. Supplied with integrated input/output unit with touch screen. Optionally the input can also be effected using a keyboard. Mould spanner sets 20-4020..23 or plaster mould sets 20-4015..16 are not included and have to be ordered in addition.

Technical specifications:

- Sample dimensions max. 280 x 340 resp. 300 x 300 mm

- Sample height 40..120 mm

- Rolling wheel Ø 203 mm, width 50 mm with 20 mm rubber layer

- Rolling section 230 mm

- Measuring section 65..165 mm

- Applied load 710 N

- User language German/English

- Temperature range 30..60° C

- Heating possible only by hot air

- Track groove depth 0..20 mm x 0.01 mm