Description

EN 12697/1 – ASTM D 8159-2018 – AASHTO

Computer controlled and operated via touch panel for the extraction and binder determination of bituminous materials within a closed system using non-inflammable solvents.

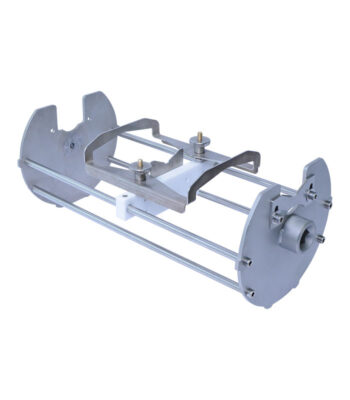

The machine can be factory-provided for either one of the following solvents: Trichloroethylene, Tetrachloroethylene or Dichloromethane (methylene chloride). Bituminous materials (up to 3.5 kg) is weighed into a sieve drum, placed into the washing chamber and then automatically washed by means of solvents and ultrasonic. Minerals are left in the sieve drum whereas binder, solvents and fillers are washed out and separated in the connected centrifuge. Filler is retained in the centrifuge cup whereas binder and solvent are separated in the connected recovery still by distillation. Solvents are reused. Two windows allow a visual check of the recovery process. After washing out, the minerals and fillers are dried automatically, and after completion of the program the process can be continued with sieve analysis. The machine is operated via software and touchpanel. The operator himself can program and memorize program sequences with depending on type of asphalt mix preselected numbers of washing and drying cycles. Main advantages of this machine are the quick extraction time of approx. 35 to 45 minutes including drying of minerals and filler and the considerably reduced ecological damage. The loss of solvent per extraction is <20 ml. For operation a centrifuge cup 20-0330 resp. 20-0335, a washing drum 20-1110.. and a washing drum cover 20-1106 is required in addition. A continous cooling water supply of 5 to 8 l/min at 3 bars and at a temperature of 10 to 15°C or a cooling unit 20-1140 has to be provided. Also for take into operation appr. 20 l of high stabilized solvent is required.

KIT Recycling (RC-Asphalt):

Two windows in the recovery cover allow an observation of the current recovery process on the clean and dirty side. A sieve inlet keep the massless asphalt components, which has not been collected in the centrifuge. Two temperature limiter with LED maintain a easy access for heating and operation of distillation processes. The new design of the vertical chiller allow a quick recovery of solvent, including a direct connection for bituminous medium into a rotary evaporation apparatus.

Solvent: stabilised Trichloroethylen HI-TRI-SMG of DOW Chemicals or Perchlorethylen