Description

EN 12697/1 – ASTM D 8159-2018 – AASHTO

For the extraction and determination of binder content in rubber modified bituminous mixtures in use with not flammable solvents as Trichloroethylene, Tetrachloroethylene and Dichloromethane as well. The extraction and distillation is PC controlled and is using Windows® as Software. Every step of the extraction is shown on the large intuitive understanding Touchpanel of the Asphaltanalysator. The user can program and storage his own test procedures in use with the different bituminous mixtures.

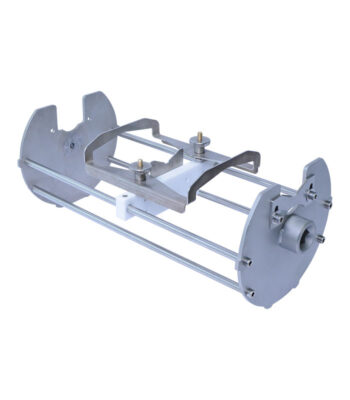

Equipped with a second solvent circuit allows the device the extraction of asphalt mixtures as stand procedure with the washing chamber or the extraction in the vertical standing unit Polygum with the automatic decantation system. The bituminous material will be separated through a continuously mixing and solving. The rubber part are solved from the asphalt material and swimming on the surface and there they will be collected by the special tool PG. The aggregates are storaged in the washing chamber, filler material is separated in the centrifuge. Bitumen and solvent will be divided from each other in the solvent recovery as usual. All parts of your bituminous mixtures are dried during the test procedure. The machine is equipped with the special collection tray PG and the mixing tool. Centrifuge cups 20-0330, washing drums 20-1112 or closing lid 20-1106 have to b ordered separately.

KIT Recycling (RC-AsphalT): Two windows in the recovery cover allow an observation of the current recovery process on the clean and dirty side. A sieve inlet keep the massless asphalt components, which has not been collected in the centrifuge. Two temperature limiter with LED maintain a easy access for heating and operation of distillation processes. The new design of the vertical chiller allow a quick recovery of solvent, including a direct connection for bituminous medium into a rotary evaporation apparatus.

Solvent: stabilised Trichloroethylen HI-TRI-SMG of DOW Chemicals