Description

EN 13286-2 – ASTM D 1557 – DIN 18127 – NF P 94-093

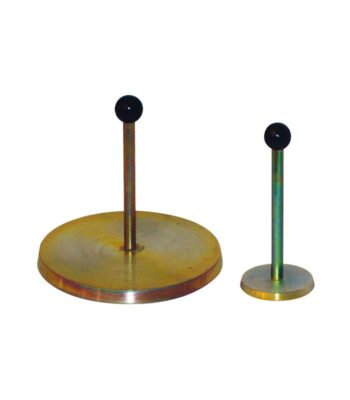

For the automatic compaction of simple and modified Proctor specimen 100 and 150 mm.

Floor model for installation on every stable base with CE safety door according to EC machinery directive. The Proctor mould is placed on the rotating base plate and the corresponding rammer is inserted into the lifting device. The drop height as well as the angle of rotation per drop are controlled by an interchangeable drive and angle plates. The movement of the impact surface towards the edge/centre/edge is made using an electric motor. The complete compaction process is controlled by a microprocessor system with universal software and pre selectable parameters:

- number of drops per layer

- number of layers

- angle of rotation per drop

- series of drops (centre/edge..)

Included in delivery are easily interchangeable drive plates for the drop heights 305 resp. 457 mm (EN-ASTM) as well as angle plates for the angle rotation per drop of 45° resp. 60° (EN). Rammers are required besides and if necessary additional accessories depending on the standard (10-18550E10 acc. to EN, 10-18550E20 acc. to DIN, 10-18550E30 acc. to ASTM… as well as Proctor moulds (10-1752…). The machine is characterised by the universal applicability with user-definable parameters and by reduced noise emission due to the safety case with door.