Our world and our climate are changing, the effects are clearly noticeable and how do we react to them? Infratest has also asked itself this question. The recent events made the medium-sized company think, so that the test equipment manufacturer began to compile a status quo with regard to its climate-friendly behavior and to collect creative ideas on how the effects can be sustainably increased. We talked about this with Managing Director Matthias Martus.

asphalt: Mr. Martus, how did you feel when you saw the pictures of the flood disaster?

Martus: I am still shocked. Climate change has been known for a long time and Infratest has been working for twelve years on concepts on how we can contribute to environmental protection and sustainability. But when you see pictures like these, you realize: it’s still not enough. For this reason, we made an analysis of all the measures that we have already established in our company in order to be able to identify potential levers.

asphalt: And what was the outcome? What were the results of Infratest and what measures are already taking effect today?

Martus: The first thing to emphasize is that we work with up to 95 % regional suppliers. This has many advantages for us, but above all the delivery and transport routes are short. The carbon footprint of our products is therefore very good up to the point of dispatch. In addition, we increase the quality of the individual parts through direct contact with our suppliers, which is why our reject rate is extremely low. Because resource efficiency is a big issue for us.

asphalt: These are important starting points, but regional production is certainly more expensive. Why doesn’t Infratest outsource production to low-wage countries?

Martus: Of course, it would be much cheaper to outsource production to cheaper countries, but at what price? Here at our company, we have the working conditions and production processes under control. We produce the electricity we need ourselves, we use mainly electric vehicles and thus ensure an environment that is as emission-free as possible. In addition, we can guarantee social and safe working conditions for our employees. This is certainly difficult to guarantee in the case of relocation to third countries. And remember: a relocation to other countries always means an intervention in the local resources, at their expense. In addition, we have an intensified procurement problem due to the effects of the pandemic. Despite the geographical proximity to our suppliers, the rapid delivery of individual parts is not always possible at the moment. The demand for raw materials exceeds the capacity of the market. Sometimes the completion of an appliance depends on only one missing part. This can be very nerve-racking. It is our duty to act in the interest of our environment and our employees. That is why we like to produce in a high-quality manner, with small master craftsmen from Zabergäu. The quality and climate protection are worth it. Our craftsmanship also makes our products very durable.

asphalt: Besides the innovative ideas, this aspect is certainly also a reason why customers choose your testing equipment.

Martus: Yes, it is up to all of us to rethink. Not only large B2C companies are responsible for the consequences of climate change. We smaller B2B companies can and must also make our contribution to slowing down global warming. When a customer buys a product from us, he supports a production with a low carbon footprint, secures jobs in Germany and makes a statement for sustainability at his workplace with an Infratest device.

aspahlt: The way you describe it, it sounds like a corporate philosophy. Is that the case?

Martus: Of course, we are gradually converting our company cars to electric or hybrid cars, and the majority of our employees live nearby and come to work on foot or by bike. In addition, we offer every employee the opportunity to charge their car free of charge at our charging stations. In this way, we also promote sustainable consumer behavior among our employees.

asphalt: Now we have talked a lot about what you are already implementing today, but what newpaths is your company taking?

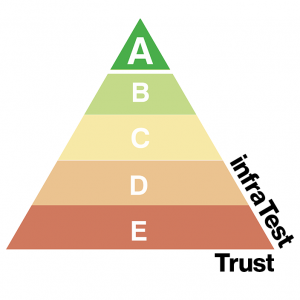

Martus: When we started setting up our measures, we quickly realized that measuring success is the sticking point. Data collection is complex and not every measure is directly controllable. In order to ensure more transparency for us and our clients, we decided to develop a scale based on a catalogue of criteria, which shows a calculated result in a traffic light system. This allows you to see at a glance how climate-friendly the product is. Our “Infratest Trust” seal sets new standards, because this is a self-imposed promise for us! A promise that we make to the next generations: In the future, each of our products will have to undergo the internal evaluation of our six criteria.

We have dedicated an entire page on our website to this topic. There we give a detailed breakdown of how the evaluations of the individual criteria are composed and how they are calculated for the result on the traffic light scale. I think with this concept we create more transparency, objectivity and trust. And who knows, maybe one day our “Infratest Trust” will become a guideline that other manufacturers in our industry will also follow? It would be great if we could inspire other companies to put their behavior to the test and come up with ways to save our world. Because in the end: One World – One Road – One Concept!

asphalt: Thank you very much for the interview!

Source: asphalt magazine, 56th volume, 6|2021 October