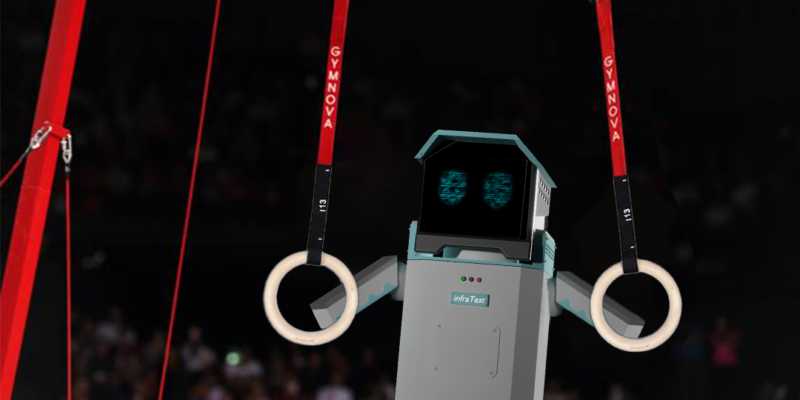

A company’s identity is not just a question of logo or slogan; it’s also defined by the way it presents itself and communicates with its customers. Indeed, it’s crucial to stand out not only through your products or services, but also through your history and values. At infraTest, we’re convinced that showing who we are is essential to creating an authentic and lasting connection with you.

That’s why we’re delighted to announce the release of our new presentation video, a project that took us six months of hard work and passion.

Showcasing our expertise

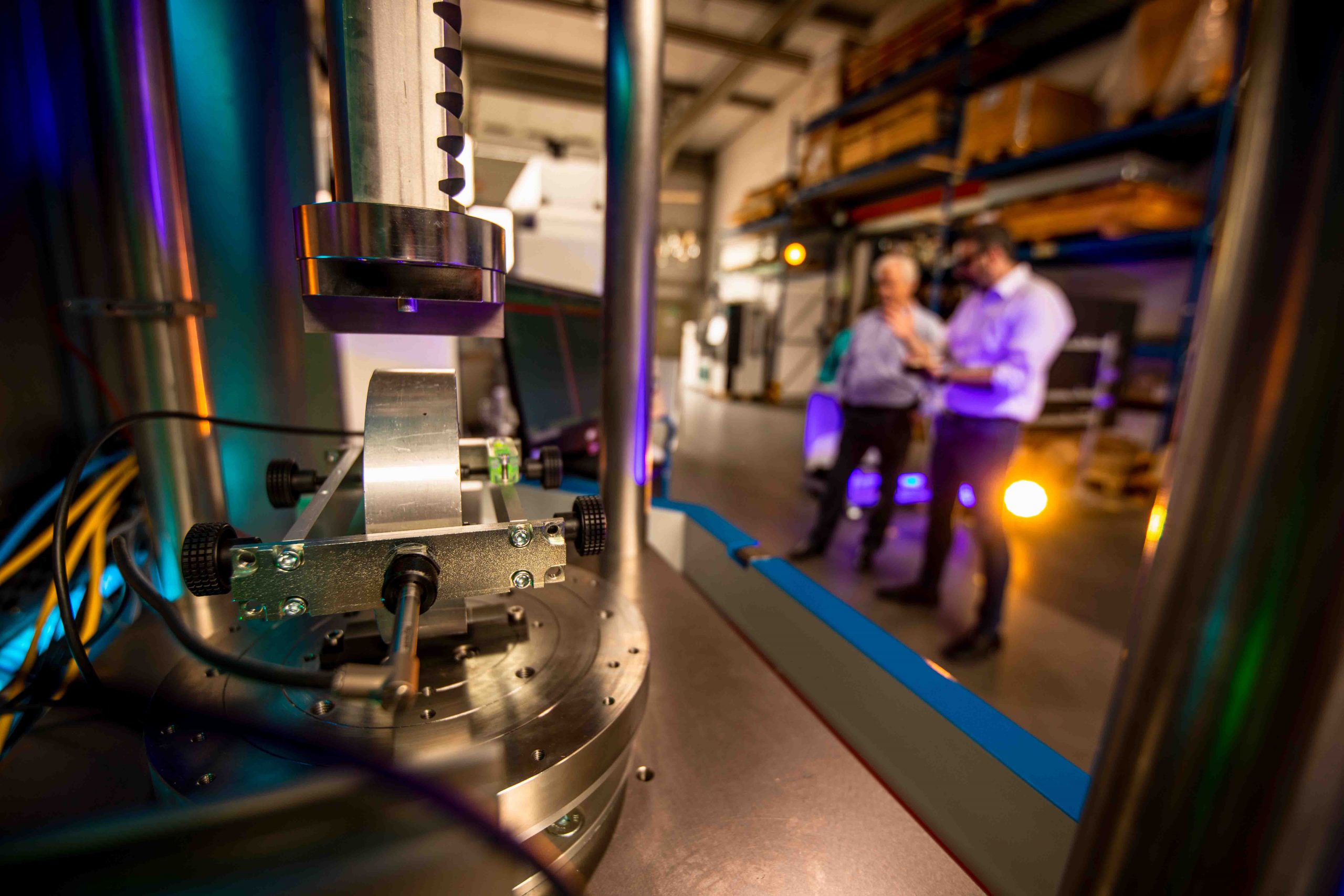

Our presentation video is a showcase for our expertise. It shows not only our know-how, but also our commitment to quality and innovation. By detailing our history, our manufacturing process and our after-sales service, we hope to help you understand why we are a leader in our field. This demonstration of competence and excellence helps to establish our credibility and enhance the value of our products and services

The creative process: a project close to our hearts

The making of this video was an exciting journey for us. We worked with Philip from Schwarzfuchs media and the Lighting and Thunder studio team, and the shoot lasted three full days. We have chosen to be as transparent and faithful as possible in this video, which is why all the actors are employees of our company. We hope you enjoy it, and maybe you’ll even be able to recognize a few of them. Let us know in the comments section!

In the end, it took six months of preparation, planning and creation to put this video together. Every step was carefully orchestrated to ensure that the final product accurately reflects our company and its values.

A glimpse of our commitment

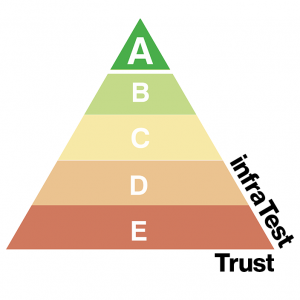

The video begins with a provocative question: “Who guarantees that our roads live up to their promises? That our concrete withstands all weather conditions? That the essential measurements are not just precise, but perfect?” Since 1991, we’ve understood building materials and their properties-our mission: to make them measurable. For over 30 years, we’ve been manufacturing test equipment with the highest standards of precision and quality. Their longevity is surpassed only by their accuracy.

We demonstrate that even if our products require maintenance, our service team is available 24/7, ready to deliver any spare part within 48 hours, anywhere in the world. Exceptional service is in our DNA. Our team works seamlessly to optimize every step and process. From the first order to final delivery, we ensure that your spare parts arrive not only quickly, but also on time.

We know our customers’ needs and the machines we manufacture! We keep all our parts in stock (over 4,000 in total) to guarantee the most responsive service. But we’re never satisfied with the status quo. Every machine and every component is continuously improved by our development team and, if necessary, completely redesigned.

From our compact standard test equipment to our turnkey laboratory solutions, we provide answers to every problem in the building materials sector. Because the challenges faced by our international customers are so diverse, innovation and individuality have always been our driving forces. Because it’s only by challenging ourselves every day, constantly re-evaluating our products and developing strong ideas and unique solutions, that we can continue to offer the best test technology solutions worldwide. Where others see only problems, we find solutions. Not just for our customers, but for us all.

We are extremely proud to share this video with you. It reflects our passion, commitment and expertise. We hope it will give you a better understanding of who we are and what we stand for. We invite you to discover it and share your impressions with us. Your opinion is invaluable and helps us to continue improving.

The video is now available on our social networks. We encourage you to watch it and discover (or rediscover) us through the eyes of those who know us best: our employees. Thank you for being part of our journey and supporting us in our mission to provide world-class testing solutions.

Follow infraTest on social networks and keep up to date with the latest news!